Pre-painted metal that looks like old rusted tin roofing. 12 colors to choose from and available in roofing, siding, flat sheets, and coil. The look of an authentic rusted metal roof, but without all of the problems.

The look of blackened steel finish without any of the problems. Pre-painted metal panels that look like a blackened steel and other dark aged metals.

Why pay for an expensive copper roof ? Metal that has been pre-painted to look like patina'd copper is a growing favorite among architects and builders. Huge cost savings when compared to real copper. Available in metal roofing, siding, flat sheets, and coil.

Metal that has been pre-painted to look like old gray zinc roofing is a growing favorite among architects and builders. Huge cost savings when compared to real zinc. Available in metal roofing, siding, flat sheets, and coil.

VARI-Cool is a polychromatic paint system that will subtly shift colors depending upon the angle it's viewed from and the lighting conditions. Available in coil, flat sheets, metal roofing and siding.

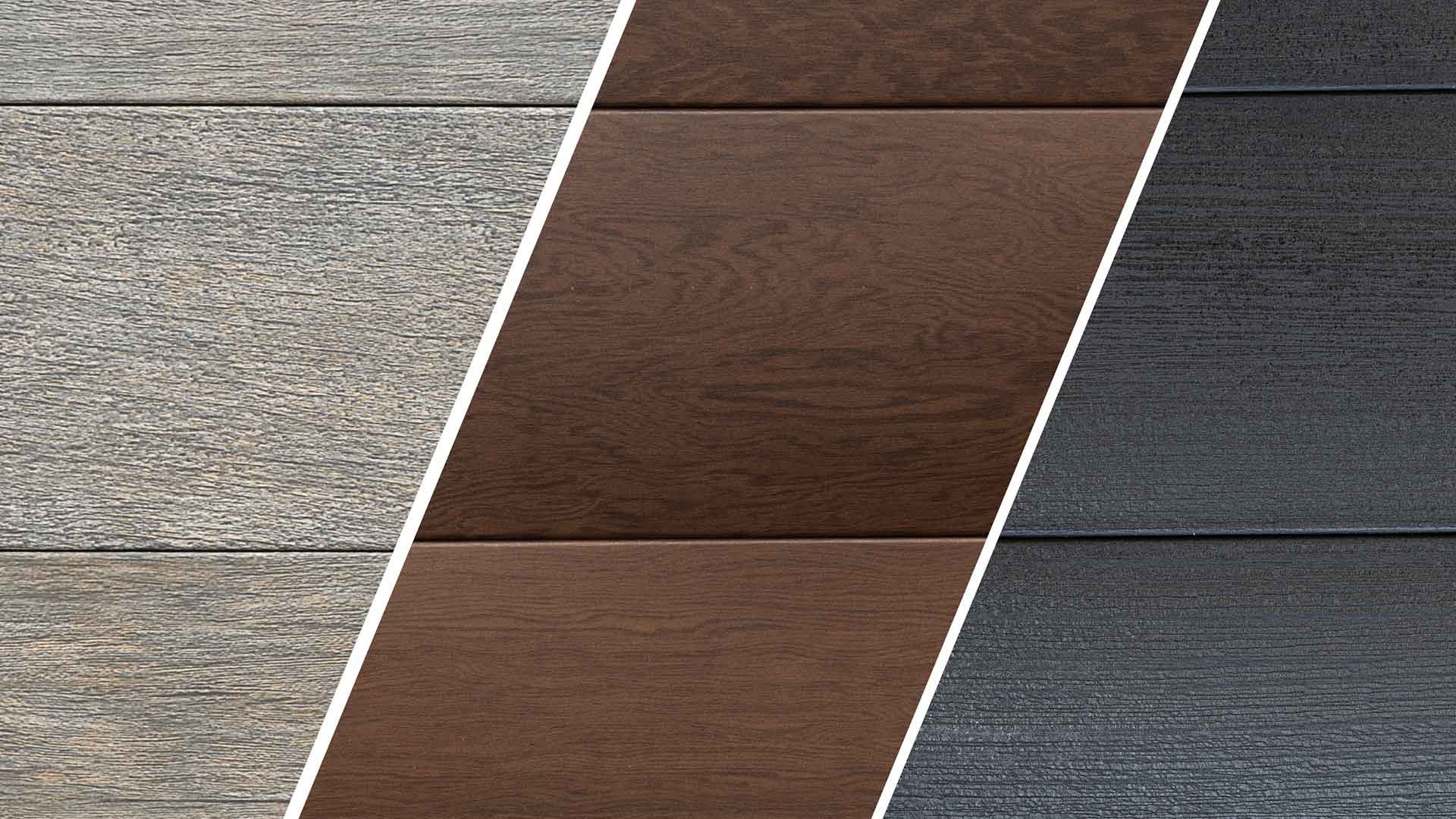

T-8 PlankWall® is a painted metal that offers architects and designers an alternative to real wood. Get the look of wood with all the benefits of metal!

View all Corten Components.

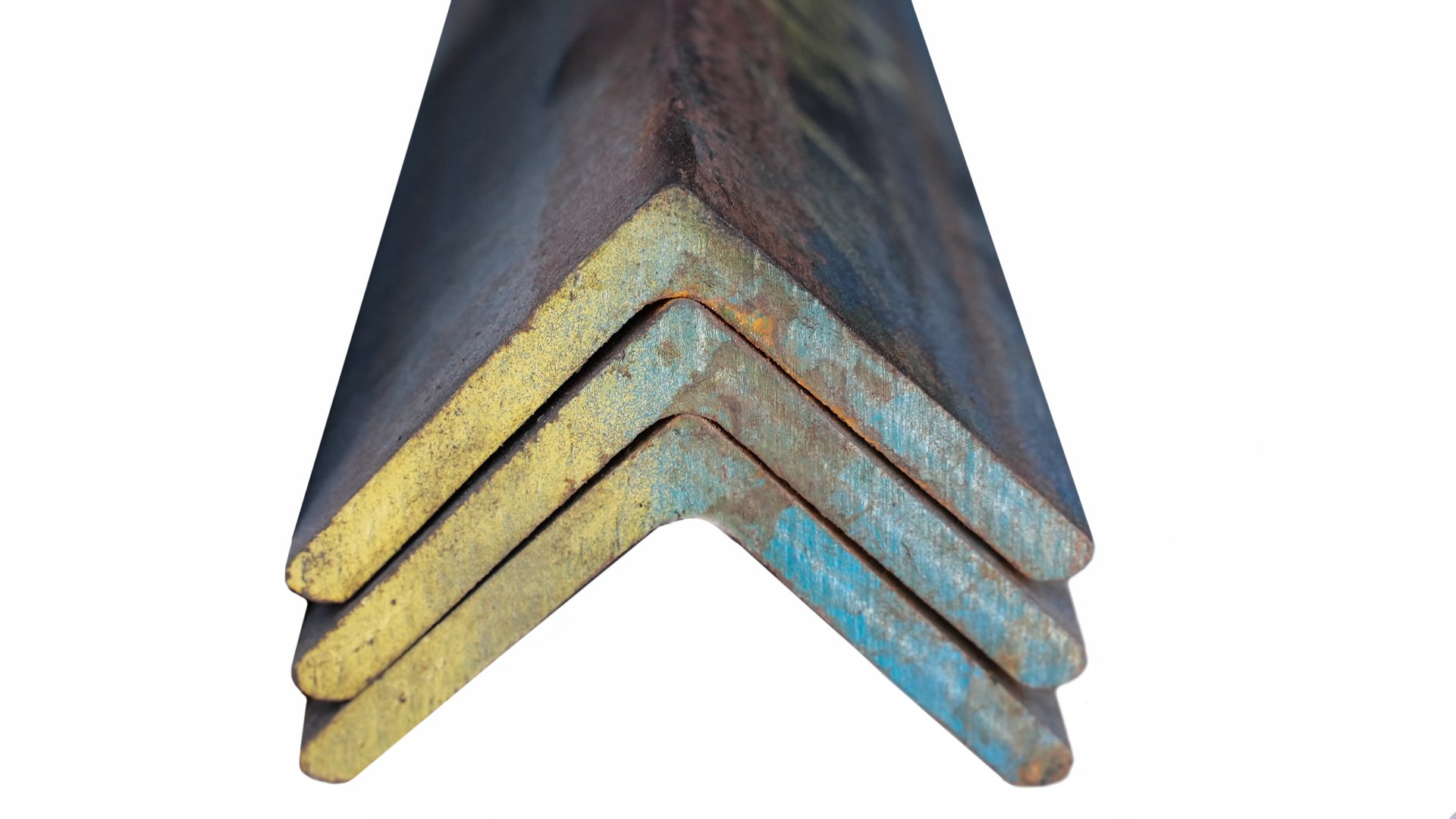

Corten angle arrives unrusted and will develop a gorgeous patina after exposure to the weather. Corten angle is in stock and available for immediate shipment.

When you are looking to purchase Corten beams it will be referred to as ASTM A588. ASTM A588 covers high-strength low-alloy structural steel shapes, plates, and bars for welded, riveted, or bolted construction but intended primarily for use in welded bridges and buildings where savings in weight or added durability are important.

Corten channels in stock. Corten A588 weathering steel channels in 20 feet lengths.

Corten steel coils are in stock in a variety of gauges and widths. A606-4 coil can be split to any weight and slit to any size. Immediate delivery in most instances.

Corten flat bar arrives unrusted and will develop a gorgeous patina after exposure to the weather. A588 flat bar is in stock and available for immediate shipment.

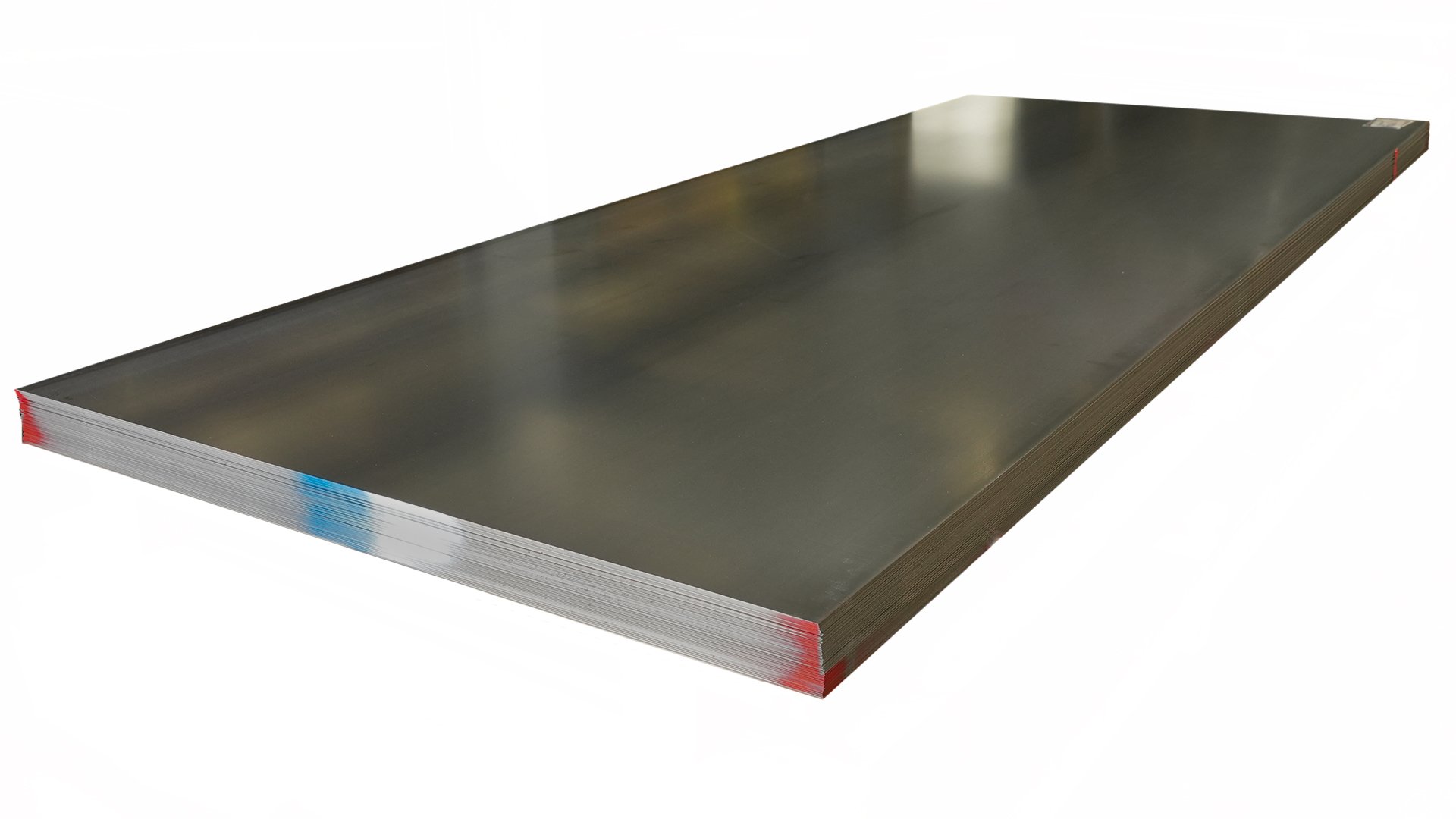

Corten flat sheets arrive unrusted and will develop a gorgeous patina after exposure to the weather. A606-4 and A588 flats are in stock at 48" or 60" widths. Custom fabrication is available.

Pre-fabricated ASTM A606-4 landscape edging with stakes offer a great simple solution for that rustic look.

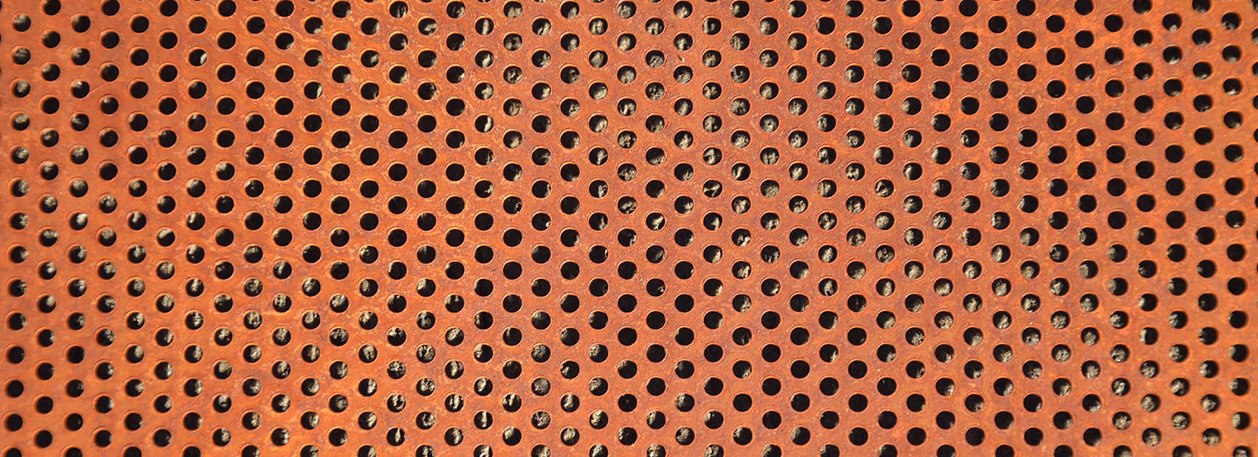

Shop a wide variety of perforated Corten® metal products in stock and have it shipped fast anywhere in the USA. We offer perforated Corten® metal in a variety of gauges and material types in various perforation patterns.

Corten pipe arrives unrusted and will develop a gorgeous patina after exposure to the weather. A847 pipe is in stock and available for immediate shipment.

4 Different sizes of planter boxes for sale. Sheet and plate cut to size for planter boxes.

Corten plate will arrive unrusted and will develop a gorgeous patina after exposure to the weather. A588 plate is in stock at 96" widths X 240" or 480" lengths. Custom fabrication is available.

Corten rounds in stock. Corten A588 weathering steel rounds in 20 feet lengths.

Corten squares in stock. Corten A588 weathering steel squares in 20 feet lengths.

When you are looking to purchase Corten tube it will be referred to as ASTM A847. ASTM A847 is a cold-formed high strength-low alloy steel that is welded and shaped into square tube and rectangular tube.

Welded wire mesh is constructed with two orthogonal wires that are joined together at their intersections using a resistance welding process to form a grid.

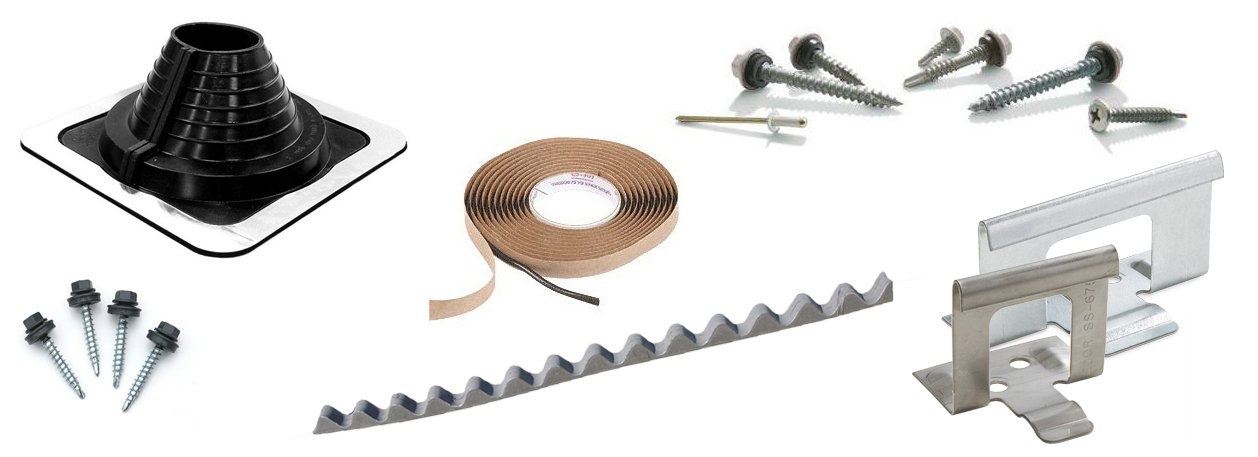

Find fasteners, anchors, bolts, hardware and more. We are a leading provider of quality fastening products for metal roofing and siding

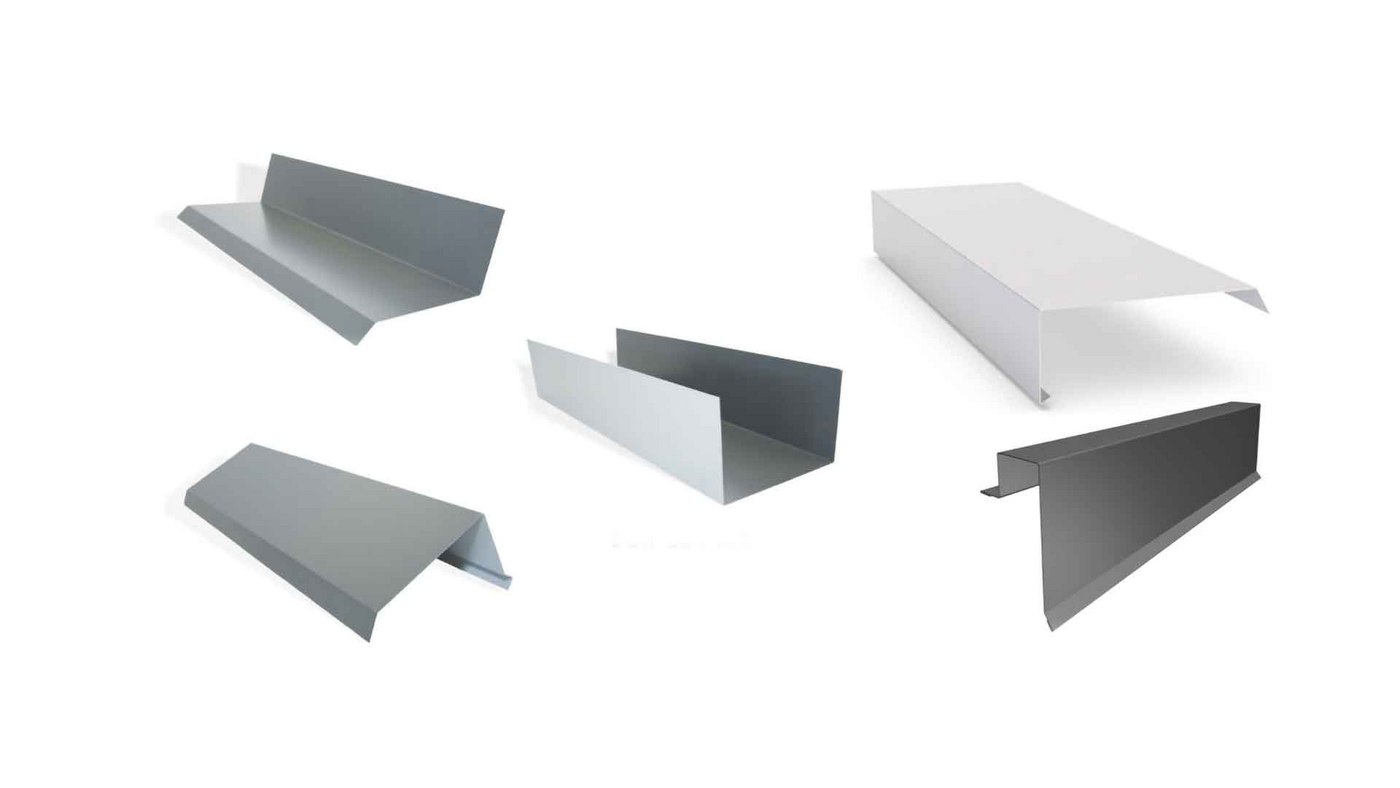

Flashing and trim available in steel with coordinating finishes and colors for your residential, commercial, industrial or agricultural metal roofing project.

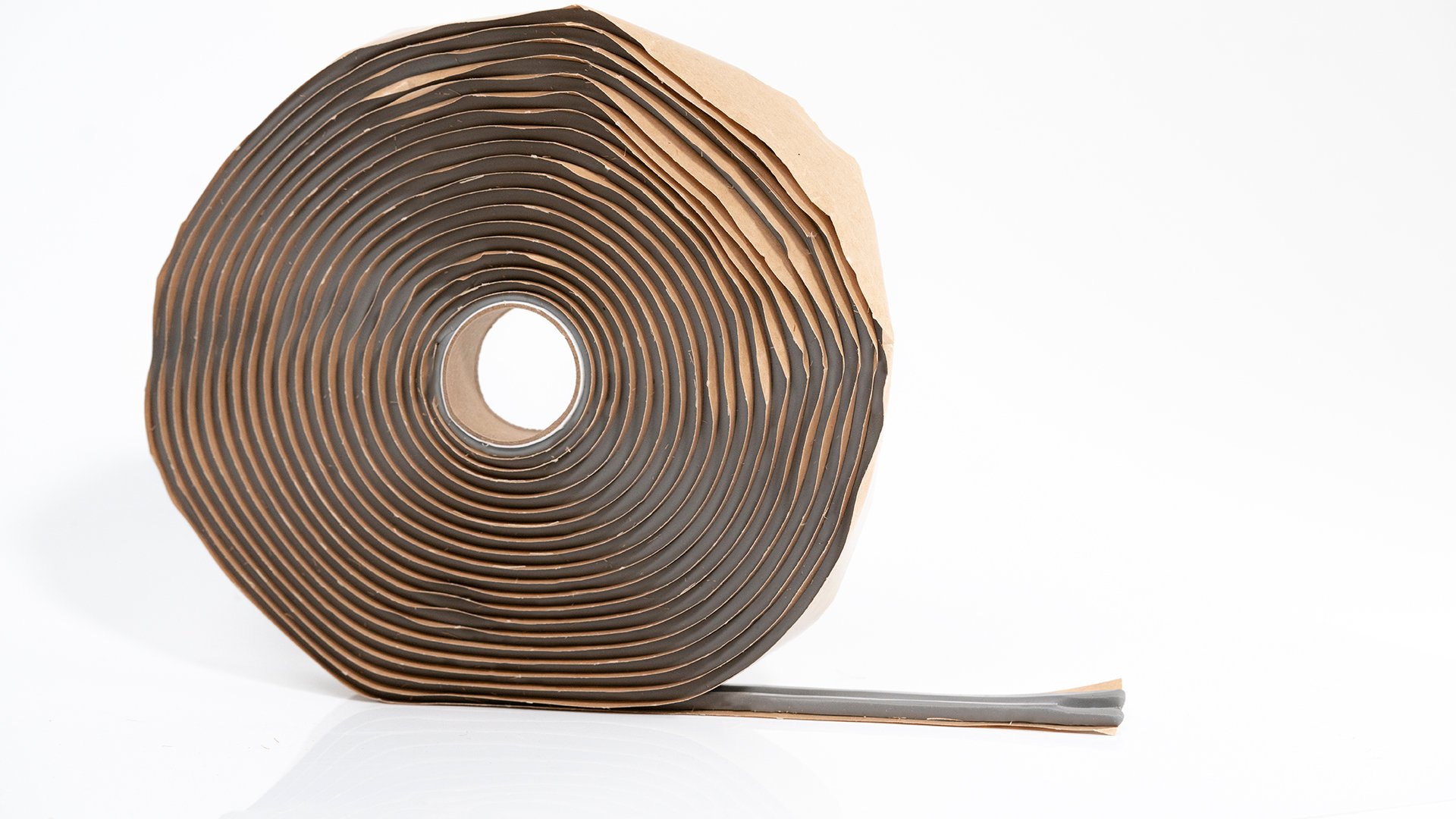

Use sealant tape at the panel laps for metal roofs to increase weather tightness. Order yours today.

Self drilling metal roofing fasteners, rivets, and clips available. All types. Metal to Wood and Metal to Metal. Painted and Galvanized.

High Quality, Natural Illuminating FRP Panels that match our most popular metal roofing profiles. Immediate Availability - 8 OZ White.

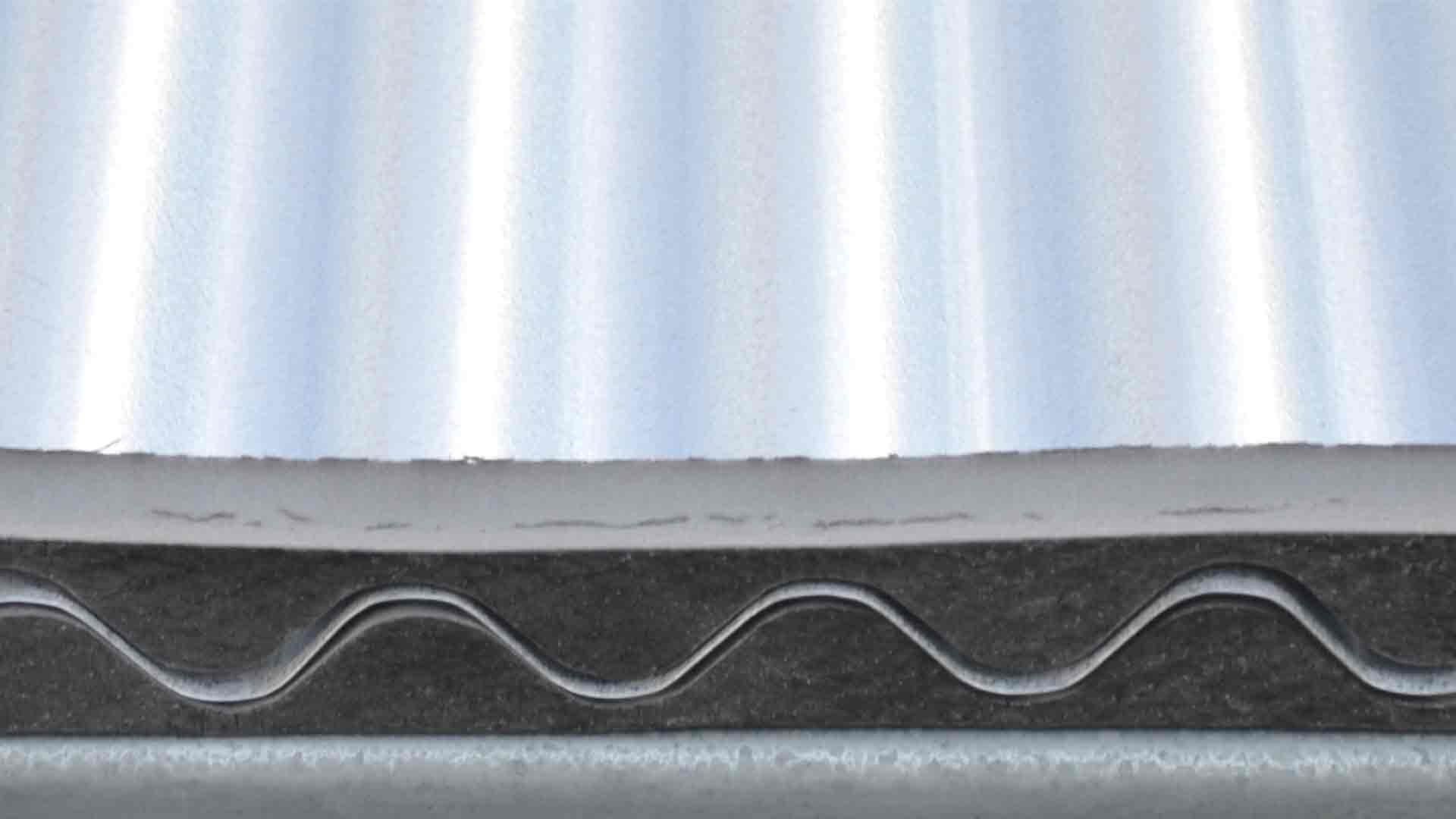

Foam closures for metal roofing and metal decking. 7/8" Corrugated, PBR Panel, Western Rib (7.2 Panel). Shop a wide variety of foam closures and foam plugs.

Galvanized square tube in stock in 14 gauge at many different lengths. Galvanized tube used for metal fence posts, metal carports, deck posts, panic bar gates, or building supports.

.jpg?width=1258&name=Metal-C-Purlins-Z-Purlins%20(1).jpg)

Metal Purlins and Cee Channel are in stock. Cee Purlins and Zee Purlins. Galvanized and Red Prime Painted. Immediate availability.

Buy Metal Roof Sealant. Available In A Variety Of Colors And Sizes. NovaFlex Construction Silicone Colored Caulk for Metal Roofing Applications.

We offer a wide range of pipe flashings in both square and round. Shop now.

Proper metal roof ventilation is essential for a healthy indoor environment. Our ProfileVent ventilation products are an intelligent solution for your roof.

Find high strength moisture protective covering for the underlayment of your metal roof.

All of S-5!’s snow guard retention systems dramatically reduce these risks associated with rooftop avalanches while maintaining the clean lines of the roof. With multiple options to choose from, you can browse our selection of metal roof snow stops to see which product will work the best for your metal roof.

S-5! provides the easiest, most cost-effective way to install solar panels directly to standing seam metal roofs.